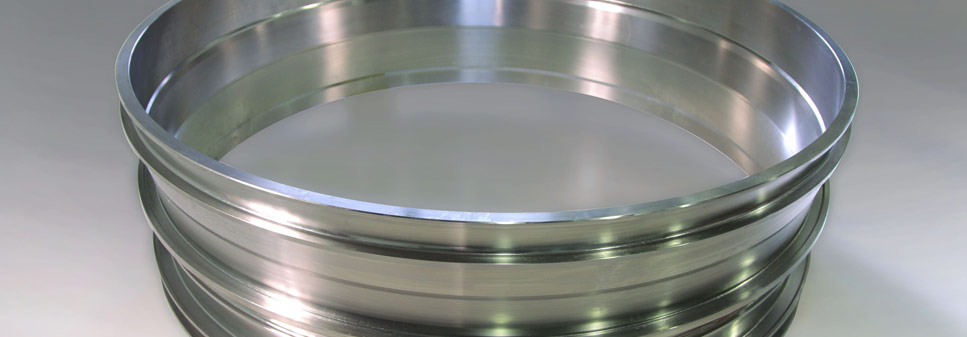

MACHINING :

Centre and vertical turning, continuous 5-axis milling.

From small to very big workpieces (up to 40 tonnes - L. 21 m), from the simplest to the most complex...

... all with the same precision.

Our ultra-efficient, ever-changing machinery means

we can guarantee high quality performance work and meet with quick turnaround and competitiveness requirements.

Related services :

sourcing, fabrication, forgings, surface treatment, non-destructive testing (US, liquid penetrant tests, magnetic particle examination)

Project management,

Kitting :

From the design to on-site installation, we produce all types of tooling and special machines with wiring,

control and fine-tuning.

Design and execution of inspection means : templates, test benches.

In order to meet with growing supplier reduction requirements, we propose our Kitting services (material sourcing, second-tier sub-contracting, tracability, inspection, associated logistics)

QUALITY CONTROL :

In air-conditioned metrology room.

Our procedures are performed in compliance with our quality assurance manual using up-to-the-minute inspection and measuring instruments.

High capacity three-dimensional inspection (stroke: 4000x3000x2000).

Our procedures comply with our Iso 9001 qualification (EN 9100 pending)